LUX –

When determining which type of metal cladding to use on the façade or roof of a building, there are plenty of options to choose from. From standing seam and interlocking systems to snaplock, cassette, and everything in-between – your final option will depend on the size of the cladding space, as well as the type of structure and desired aesthetic.

Keep reading to familiarise yourself with the most common forms of metal roof and wall cladding, as well as to learn about a unique product that has been dubbed “the future of steel”.

Different Types of Metal Roof and Wall Cladding

When it comes to metal cladding, there isn’t a ‘one-size-fits-all’ solution. Here are the various systems of metal cladding that are commonly used on the facades and roofs of both residential and commercial buildings.

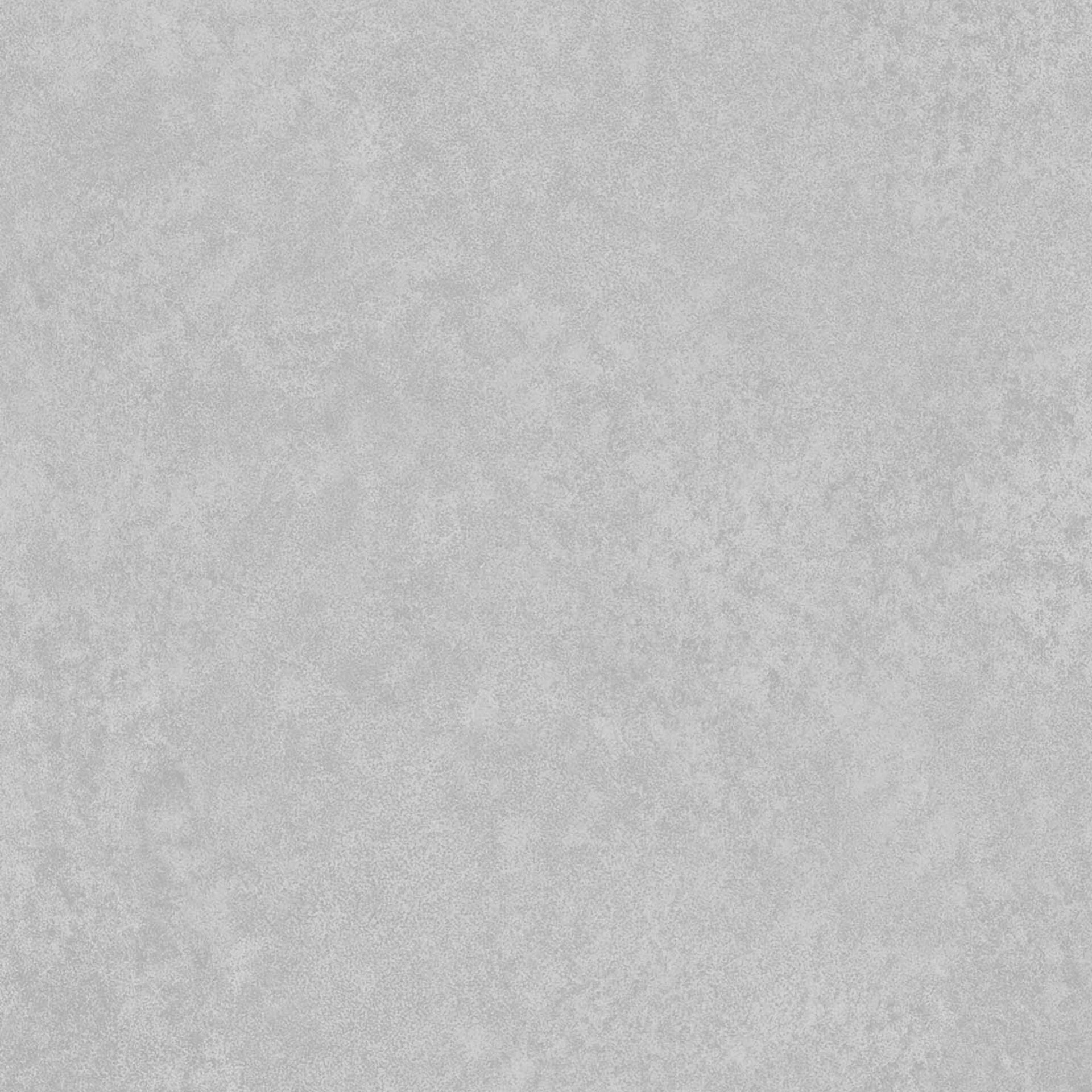

Standing Seam

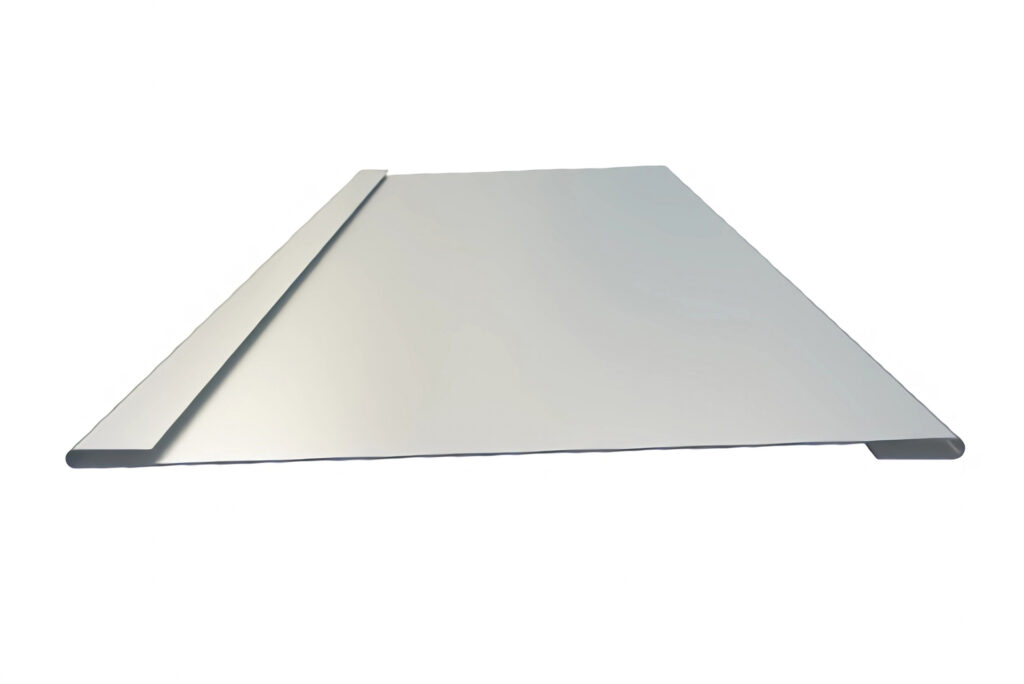

Standing seam is one of the most distinguishable metal cladding systems, thanks to its distinctive double-folded connections between each panel. It’s popular among architects due to its versatility and uniform design, making it a strong contender for practically any roof shape.

Standing seam profiles are used on both roofs and facades, and are particularly well-suited to very large cladding surfaces, as well as buildings in regions prone to regular snowfall, high winds, and heavy rain. This is due to its superior water and wind resistance capabilities.

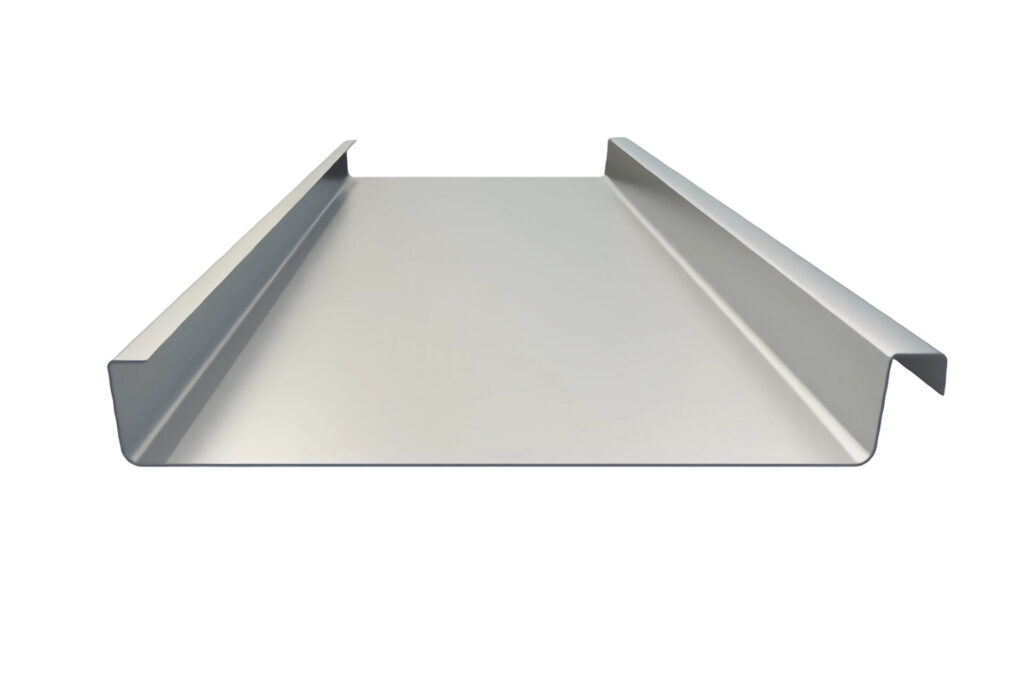

Snaplock

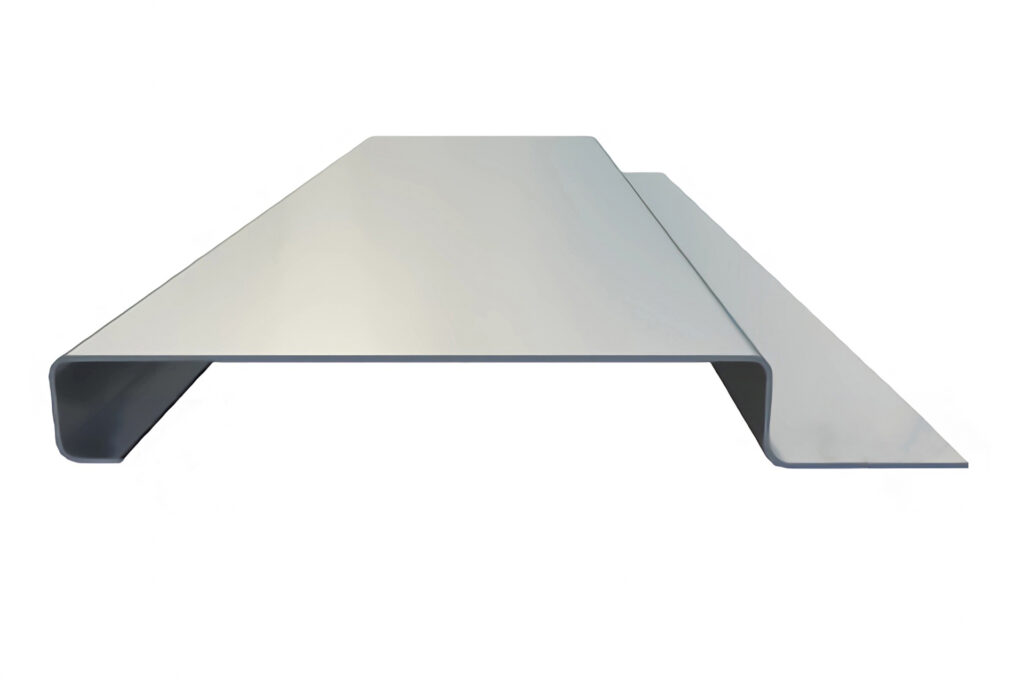

A snaplock cladding system contains a similar ribbed profile to the standing seam, however these panels are designed to ‘snap’ together. This quick and easy installation doesn’t require specialist tools either, making it a simpler – yet just as stunning – alternative.

It also has a hidden clip profile and is widely utilised in both modern and classic architectural facades, as well as major residential or commercial buildings.

Nailstrip

Nailstrip shares similar aesthetics with Standing Seam and Snaplock. The ease of installation offered by Nailstrip makes it a favourite among beginner installers and owner builders. Architectural façade can be achieved easily without the need for clips or special seam tools when installing.

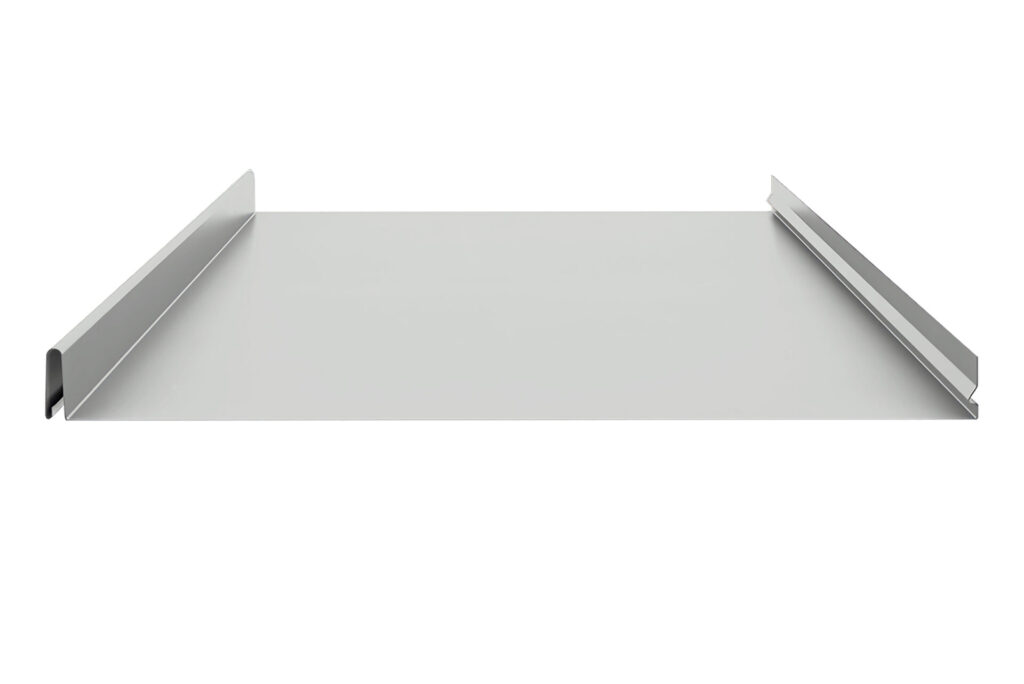

Interlocking

Interlocking is another popular system; however, it is suitable for wall cladding only. Interlocking is used to create an ultra-modern aesthetic for both residential and commercial structures.

Architects are particularly drawn to the elegant, sleek, and contemporary profile design of interlocking, as it creates an utterly flat surface with a signature shadow-line express joint.

Interlocking panels can run both vertically and horizontally, as well as diagonally.

Flatlock and Shingle

Flatlock and shingle cladding systems have the same profile design, but once folded and installed, their differences become evident.

Flatlock panels link together to provide a thin, versatile, and level facade. The system can also be fitted in reverse, resulting in deeper express lines. This style is known as Reversed Flatlock.

Shingled metal wall cladding, on the other hand, can be produced by folding panels into interconnected tile forms. This creates eye-catching and architecturally stunning patterns within a building’s metal façade.

Both wall cladding systems are typically chosen when slimmer walls are required.

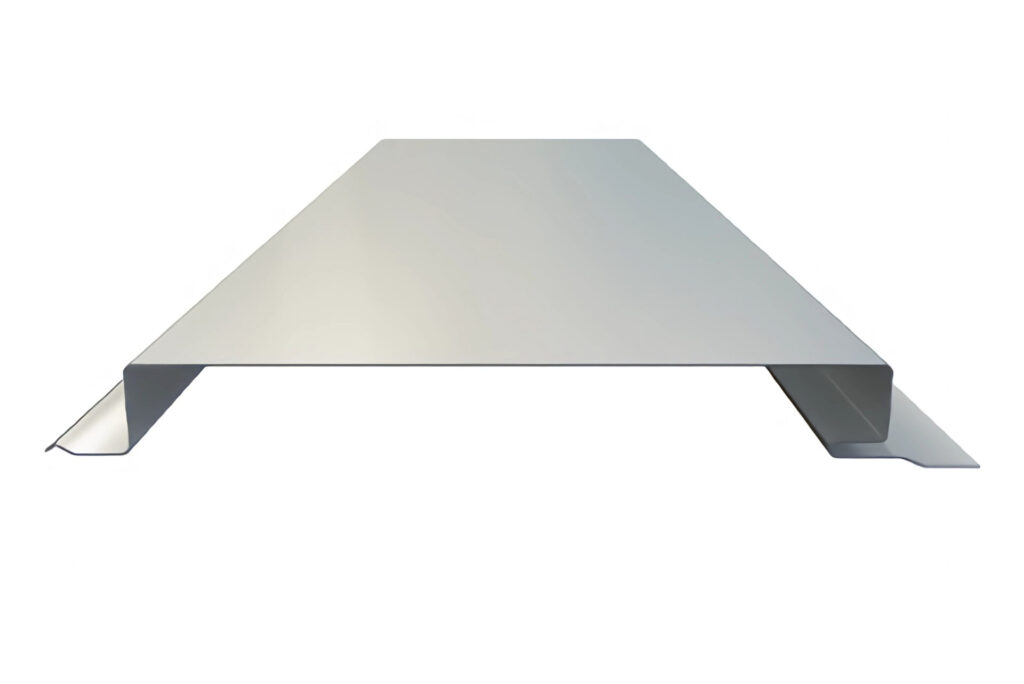

Cassette

With this hook-on metal cladding system, cassette panels are bent and secured to an aluminium frame with invisible clips and top hats. It’s a versatile roof and wall cladding solution that’s popular for vertical and horizontal placement on low- to high-rise buildings.

The open-jointed cassette model is also great for large cladding areas, since it can be used with panels up to 13 feet in length.

The end result is modern, flat, and at times, futuristic in appearance.

Corrugated

A classic and versatile profile featured in a variety of applications including roofing, walling and fencing. Corrugated sheeting is complementary to both traditional and contemporary architecture, used in both domestic and industrial buildings.

Custom/Bespoke Panels

Specialist roof and wall cladding manufacturers can also create custom architectural panels to suit the individual needs of a project. This may include altering an existing cladding system, such as those mentioned above, or creating one that is completely unique and hasn’t been used before.

Unleash Your Creativity with UniCote® LUX

While most metal cladding solutions come in a range of standard colours or styles, architects who are looking to design outside of the box regularly turn their attention to UniCote® LUX.

UniCote® LUX is a premium patterned steel product mainly used for architectural panels, wall cladding (interior and exterior) and garage doors. It can also be used in commercial roofing applications, however UniCote® LUX is more common within architectural designs – particularly where the roofing profile must match the wall cladding.

UniCote® LUX is a game-changer in the field of metal cladding, as it allows architects to truly unleash their creative potential in ways rarely seen before. The product combines the world’s best coil coating technology with thorough testing to Australian Standards. Additionally, UniCote® LUX offers exceptional performance in the tough Australian climate, as well as a striking patterned and textured finish that’s built to last. By combining the most durable paint systems and protective coatings available, the long-lasting nature of UniCote® LUX offers warranties up to 25 years on a wall cladding application.

UniCote® LUX is available in a wide range of finishes, including: Weathered iron, Corten Red, Ashwood, Midnight Matt, Maple, Wenge, Zinc Graphite, Silver Quartz, Saffiano, Metal Stone, Spectrum and Pentagon.

Corten Red and Weathered Iron are perhaps two of the most unique products of their kind, as they allow architects, builders, and homeowners to achieve the look of rusted or weathered iron and still obtain warranty for the product.

Whilst this aesthetic can be achieved with standard corten steel, the final result can be unpredictable and although the corten is designed to just rust or weather on the surface, manufacturers may not provide a warranty on their product.

UniCote® LUX products, on the other hand, are a printed pattern on steel. Although they look incredibly realistic, their rusted or weathered aesthetic poses no risk, allowing the product to have full warranty.

UniCote® LUX weathered steel patterns won’t bleed or provide run offs and timber patterns won’t require the laborious upkeep of real timber to maintain their aesthetics.

UniCote® LUX is the future in Australian pre-painted steel design. Want to achieve a superior and unique exterior for your next project? Explore our range of UniCote LUX today or contact our team for more information.