UniCote Extreme

For demanding environments

UniCote® Extreme is made from marine grade aluminium alloy – a premium roofing and cladding solution with the highest durability, formability and colour retention. UniCote® Extreme is made from the same marine grade allow used to build boats, its superior corrosion resistance is designed for all applications, including very severe marine and heavy industrial environments.

Colours and Patterns

Stocked colours

Made to order

The extra benefits of UniCote® Extreme

Inspiring building design and architectural

creativity, with a choice in style and performance.

-

Aluminium Doesn’t Rust -

Marine Grade Aluminium -

BEST IN CLASS WARRANTIES -

Exceptional Design Life -

Tested in Australian Conditions -

Wide Range of Colours -

Non-combustible -

Thermal efficiency

Tested for peace of mind.

Again and again.

UniCote® Steel’s performance testing is a testament to its unwavering commitment to quality and durability, instilling unwavering confidence in architects and homeowners alike. Rigorously tested beyond industry standards, it boasts exceptional strength, corrosion resistance, and weather endurance, ensuring architectural visions will stand the test of time.

Homeowners can take comfort in knowing that UniCote® Steel guarantees safety, security, and long-lasting beauty, providing the peace of mind needed to turn houses into homes built to last.

Technical, Warranty & Downloads

Behind all the beauty and performance is the meticulous technical detail that supports our strong warranty position. With our unwavering support and protection, you can proceed with absolute confidence, knowing that your vision is backed by a steel product that is engineered to excel in every aspect.

Technical Information

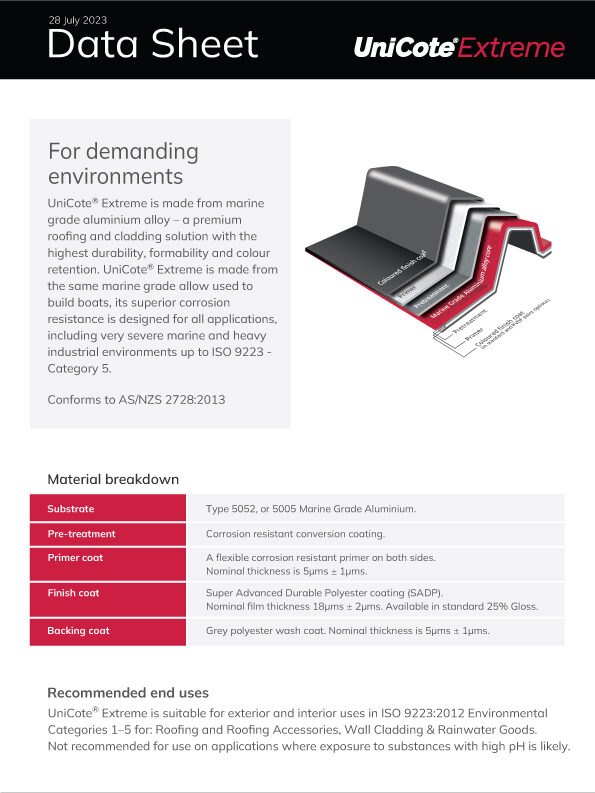

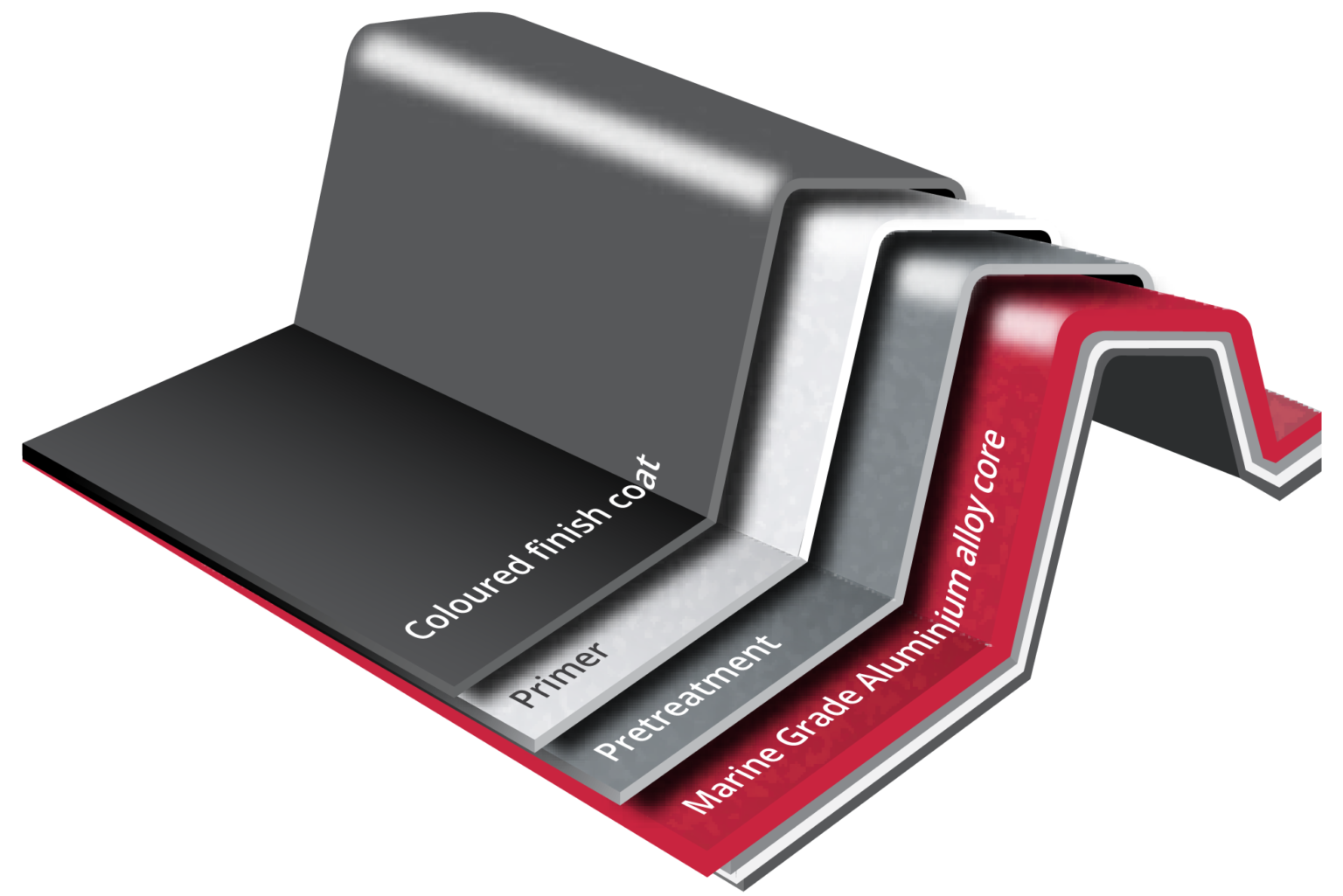

Substrate

Type 5052, or 5005 Marine Grade Aluminium.

Pre-treatment

Corrosion resistant conversion coating.

Primer

A flexible corrosion resistant primer on both sides. Nominal thickness is 5µms ± 1µm.

Finish Coat

Super Advanced Durable Polyester coating (SADP). Nominal film thickness 18µms ± 2µms.

Backing Coat

Grey polyester wash coat. Nominal thickness is 5µms ± 1µm.

Gloss

Available in standard 25% gloss.

Protective Film

Products are supplied with an easily removed strippable protective film. This material has a relatively short life span when exposed to sunlight and weather. It should be removed either just before, or immediately after installation.

Warranty

Depending on the environment and distance from water, UniCote® offers warranties of differing lengths on UniCote® Extreme for residential, commercial and industrial buildings, in environments with heavy industrial pollutants, high geothermal activity and very severe marine environments.

Warranty up to 30 years

Complete our online warranty form and receive a pre-approval warranty within 48 hours!

Downloads

Tell us about your project

Send us an email using the form or call us on

1800 UNICOTE (1800 864 268)

We can help you with:

– Choosing the right material for your location

– Discuss profiles suitable for your design

– Work with you on project budgets and estimates

– Identify local suppliers and

– Pre-approved warranties

"*" indicates required fields