UniCote Coastal

For that extra protection

A steel material that heals its own cuts.

UniCote® Coastal takes our standard aluminium/zinc alloy-coated steel substrate to the next level with the addition of magnesium. This enables the zinc to ‘flow’, which seals the cut edges preventing exposure to premature corrosion. This makes it ideal for harsher environments and those nearer the coast.

Why use UniCote® Coastal?

I’m building near the water

UniCote® Coastal is suitable for projects

0 – 400m+ from marine influence:

- ISO 9223:2012 – Category 1-4

I need corrosion resistance

UniCote® Coastal self-heals steel along the cut edges thanks to the magic of magnesium:

- AM210 Zinc/Aluminium/Magnesium Alloy

I want a superior product

UniCote® Coastal has a 30% thicker magnesium coating vs other industry comparable material.

- 210 gms/m² magnesium coating

It needs to be non-combustible

Suitable for Bushfire Attack Level: BAL FZ

- Fire-rated AS1530.3

- Conforms to AS/NZS2728:2013 / AS1397:2021

I need inspiration

UniCote® Coastal is readily available in 6 popular finishes.

Also available in 54 finishes in small order quantities and approximately 6-8 week lead time.

I want an individual design

UniCote® Coastal can be roll-formed into a variety of architectural cladding profiles and popular roofing profiles including:

- Interlocking

- Nailstrip

- Snaplock

- Standing Seam

- Shingles/Flatlock

- Corrugated

- Five Rib

- Concealed Deck

- and more…

It needs to be a proven product

UniCote® Coastal has been used in landmark projects such as:

- Queensland Country Bank Stadium

- Brisbane International Cruiseship Terminal

- NSW Royal Air Force Base

- Queen VIC Market

- Bondi Icebergs

- Portsea Hotel

I need more information

Contact us! We’d love to discuss your project and help you with specifications, warranty, budget and supply.

1800 UNICOTE (1800 864 268)

How to specify UniCote® Coastal

Proprietary specification examples for UniCote® Coastal

Schematic Design Specification:

Project: Coastal Residence

Exterior Cladding Specification:

Brand: UniCote®

Product: UniCote® Coastal

Color/Finish: Off White

Profile: Vertical Standing Seam

Supplier/Manufacturer: (contact UniCote® to help you find a supplier for your project)

Thickness: 0.55mm

Description:

Use UniCote® Coastal steel in an Off White colour in a standard finish. The cladding should be manufactured into a vertical standing seam profile by an approved supplier to enhance the modern aesthetic of the residence.

Detailed Design Specification:

Project: Coastal Commercial Building

Exterior Roofing Specification:

GENERAL:

Brand: UniCote®

Product: UniCote® Coastal

Color/Finish: Monolith

Profile: Concealed Deck

Supplier/Manufacturer: (contact UniCote® to help you find a supplier for your project)

Thickness: 0.48 mm

Compliance:

AS1530.3

AS/NZS 2728:2013

AS 1397:2021

BAL FZ

Steel Substrate: AM210. Hot-dipped Zinc/Aluminium/Magnesium alloy coated steel coil. Alloy coating weight; Minimum 210gms/m²

MATERIAL PROPERTIES:

Coating Mass: AM210 (210gms/m² minimum magnesium coating

Coating System:

- Primer: A flexible corrosion resistant primer on both sides. Nominal thickness is 5µms ± 1µms.

- Finish Coat: Super Advanced Durable Polyester coating (SADP). Nominal film thickness 18µms ± 2µms. Available in standard 25% Gloss.

- Backing Coat: Grey polyester wash coat. Nominal thickness is 5µms ± 1µms

PERFORMANCE REQUIREMENTS:

Corrosion Resistance: Suitable for corrosive environments. ISO 9223:2012 – Category 1-4

UV Resistance: High UV resistance to prevent color fading. Meets the requirements of AS/NZS2728:2013 Section 2.8 and Table 2.4.

Impact Resistance: No loss of paint adhesion after a test piece is struck on the reverse side with a specified force, in line with the test methodology AS/NZS2728:2013 Table 2.2 and Appendix E.

Disclaimer:Remaining specification details (for example: installation and maintenance) are design dependent and will be up to architects and engineers to specify. What we have provided above is a specification example relating to UniCote® Coastal as a material in a Monolith finish ONLY. Please contact us and we will help you find a supplier to source your project, provide guidance on budget, help you with a warranty pre-approval for your specific project location to specify in your design for UniCote® Coastal.

Colours and Patterns

Stocked colours

Made to order

Tested for peace of mind.

Again and again.

UniCote® Steel’s performance testing is a testament to its unwavering commitment to quality and durability, instilling unwavering confidence in architects and homeowners alike. Rigorously tested beyond industry standards, it boasts exceptional strength, corrosion resistance, and weather endurance, ensuring architectural visions will stand the test of time.

Homeowners can take comfort in knowing that UniCote® Steel guarantees safety, security, and long-lasting beauty, providing the peace of mind needed to turn houses into homes built to last.

Technical, Warranty & Downloads

Behind all the beauty and performance is the meticulous technical detail that supports our strong warranty position. With our unwavering support and protection, you can proceed with absolute confidence, knowing that your vision is backed by a steel product that is engineered to excel in every aspect.

Technical Information

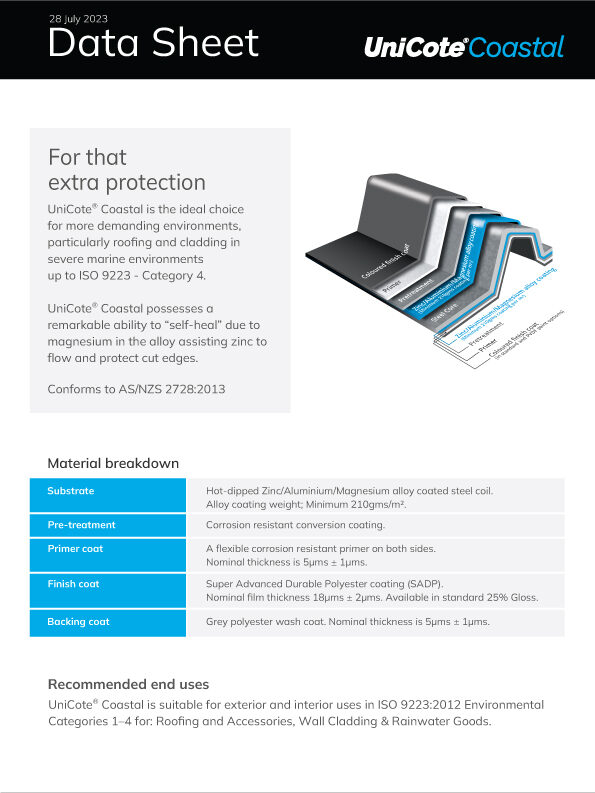

Substrate

AM210.

Hot-dipped Zinc/Aluminium/Magnesium alloy coated steel coil. Alloy coating weight; Minimum 210gms/m².

Pre-treatment

Corrosion resistant conversion coating.

Primer

A flexible corrosion resistant primer on both sides. Nominal thickness is 5µms ± 1µms.

Finish Coat

Super Advanced Durable Polyester coating (SADP). Nominal film thickness 18µms ± 2µms. Available in standard 25% Gloss.

Backing Coat

Grey polyester wash coat. Nominal thickness is 5µms ± 1µms

Gloss

Available in standard 25% gloss.

Protective Film

Products are supplied with an easily removed strippable protective film. This material has a relatively short life span when exposed to sunlight and weather. It should be removed either just before, or immediately after installation.

Warranty

Depending on the environment and distance from water, UniCote® offers warranties of differing lengths on UniCote® Coastal for residential, commercial and industrial buildings, in moderate-severe marine and industrial environments.

Warranty up to 30 years

Complete our online warranty form and receive a pre-approval warranty within 48 hours!

Downloads

Applications

Inspiration

Case Studies

Tell us about your project

Send us an email using the form or call us on

1800 UNICOTE (1800 864 268)

We can help you with:

– Choosing the right material for your location

– Discuss profiles suitable for your design

– Work with you on project budgets and estimates

– Identify local suppliers and

– Pre-approved warranties

"*" indicates required fields